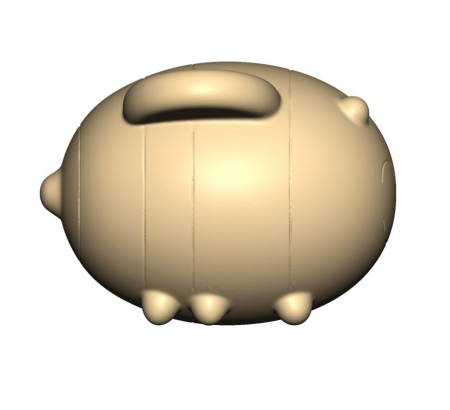

anti stress balls manufacturer

An anti stress balls manufacturer specializes in designing and producing high-quality stress relief products that cater to diverse customer needs. These manufacturers employ advanced manufacturing processes and premium materials to create durable, effective stress balls that provide therapeutic benefits. The production facilities typically feature state-of-the-art equipment for molding, filling, and quality control, ensuring consistent product quality. Modern anti stress balls manufacturers incorporate innovative features such as various density levels, textures, and sizes to accommodate different user preferences and therapeutic requirements. They often utilize specialized materials like memory foam, gel, or TPR (Thermoplastic Rubber) to enhance the tactile experience and durability of their products. The manufacturing process includes rigorous testing phases to ensure product safety, durability, and effectiveness in stress relief. Many manufacturers also offer customization options, including corporate branding, different colors, and specialized shapes to meet specific market demands. These facilities maintain strict quality control measures and often hold relevant safety certifications to ensure their products meet international standards. Additionally, they frequently collaborate with healthcare professionals and stress management experts to develop products that effectively address various stress-related concerns.