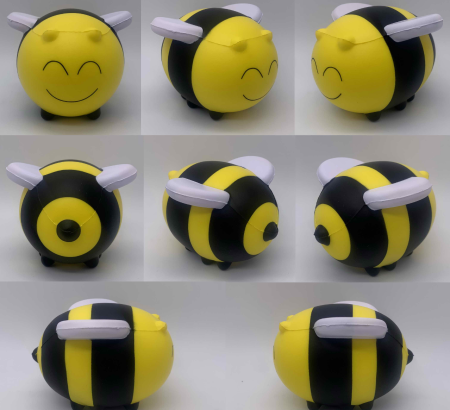

anti stress balls factory

An anti stress balls factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality stress relief tools. The facility combines advanced injection molding technology with precision material mixing systems to create perfectly balanced stress balls that offer optimal squeeze resistance and durability. The factory utilizes automated production lines equipped with quality control checkpoints, ensuring consistent product quality throughout the manufacturing process. Advanced polymer processing units enable the creation of various textures and densities, catering to different user preferences and therapeutic requirements. The facility's material science laboratory continuously develops and tests new compounds to enhance product performance and durability. Climate-controlled storage areas maintain material integrity, while sophisticated packaging systems ensure products reach customers in perfect condition. The factory's production capacity typically ranges from 50,000 to 100,000 units per day, with flexible manufacturing capabilities allowing for customization in size, color, and texture. Modern equipment monitors and maintains precise temperature and pressure conditions during production, resulting in stress balls with optimal elasticity and resilience. The facility also incorporates sustainable manufacturing practices, including material recycling systems and energy-efficient machinery.